SCADA Full Form | What is Supervisory Control and Data Acquisition

What is the full form of SCADA

SCADA: Supervisory Control and Data Acquisition

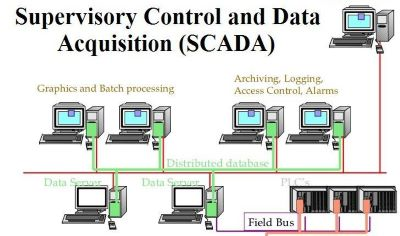

SCADA stands for Supervisory Control and Data Acquisition. It is a computer system designed to gather and analyse real-time data. It is used to control and monitor the equipment and manufacturing processes in various industries in different fields such as water and waste control, telecommunications, oil and gas refining, power generation, and transportation. SCADA systems were used for the first time in the 1960s.

SCADA controls the functioning of equipment involved in manufacturing, production, fabrication, development, and more. It is also used for infrastructural processes such as gas and oil distribution, electrical power distribution, water distribution, and more. Thus, it has reduced human intervention to a great extent.

Furthermore, it is also used by industrial organizations to accomplish the followings tasks.

- To control industrial processes locally as well as at remote locations

- To monitor, gather and process real-time data

- To interact with devices such as sensors, valves, motors, pumps, and more using human-machine interface (HMI) software

- It comprises both software and hardware

It comprises both software and hardware, different industries have different requirements, so there may be some differences in their SCADA systems, but still, some features are common for all, such as:

- Graphic interface

- Process mimic

- Real-time checking

- Alarm system

- Data acquisition

- Data analysis

- Report generator

How SCADA Systems Work:

Let us take an example of a leak on a pipeline. When a pipeline starts leaking, the SCADA system gathers information and forwards it to a central site and thus alerts the home station about the leak. It also analyses the situation, such as how big is the leak and how much water is being released.

A SCADA system can be very simple such as which are used to monitor the environmental conditions of a small office building or complex or can be very advanced such as which are used to monitor the activity in a nuclear power plant or the activity of a municipal water system.